Specialized fields ours

SHM Trading and Manufacturing Co., Ltd., with many years of experience, we have researched and developed (R&D) the product ”high-temperature bearing” with the GMW brand. GMW with special design, easy to operating temperatures above from 150°C (302°F) to 400°C (752°F). High temperature bearings are manufactured to solve problems related to high temperature environments, dry environmental conditions… available for low speeds and fast speeds

LEARN MORE

What we do

With the GMW brand High temperature bearings, used as replacements during maintenance and overhaul of industrial equipment… All high-temp bearings are maker of main raw materials of European suppliers, the products have been meeting strict requirements from customers with quality, reasonable price and perfect service…

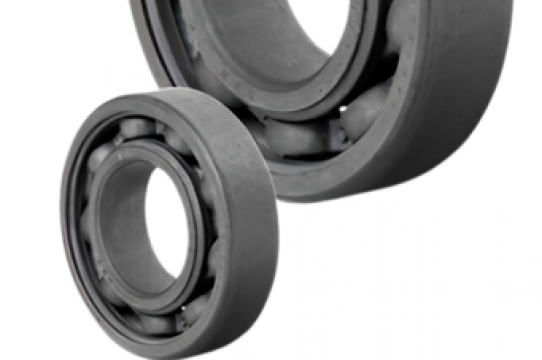

High Temperature Bearings

Bearings with operating temperatures above 150°C are high-temperature bearings. With special design, easy operation at temperatures from 150°C (302°F) up to 400°C (752°F). High-temp bearings are a line of balls manufactured to solve problems related to high temperature environments, dry environmental conditions. Has option slow rotation speeds and fast speeds for choose

High Temperature Grease

High Temperature grease, Extreme Pressure Grease and a temperature range from 150°C to 350°C, It is ideal for use in manufacturing facilities where safety, thermal stability, performance and extended service life are critical lubricant requirements. It is resistant to detergents and salt water, will not dry out, resists corrosive chemicals and will not separate.

Our grease lubrication are sourced from Europe and certified according to the standard 91/155 EEC

The Secret of Success

GMW with special design, easy to operating temperatures above from 150°C (302°F) to 400°C (752°F). High temperature bearings are manufactured to solve problems related to high temperature environments, dry environmental conditions… available for low speeds and fast speeds

Advantages:

Increased radial clearance (multiple of C3, C4 and C5) compensation for temperature induced deformations of the production goods

Riveted sheet steel cage provides high stability at low friction

Manganese phosphate coating (according to EN ISO 9717) ensures increased protection against corrosion, good adhesion of lubricants and better runability.

All suffix HT1 (350°C) , HT2 (280°C), HT3 (300°C), ENC330°C (Enhanced+), HT4 (400°C), T150 (150°C), T200 (200°C), T250 (250°C), T250X (250°C) and HT2/G (300°C) – bearings are available open, with steel (2Z) (Z) (2RS1) shield on one or both sides

Lubricants:

GMW offers four standard lubricants for High-temp Deep Groove Ball Bearings. Additionally, our coated bearings can be filled with individual grease as required by the customer

Our grease lubrication are sourced from Europe and certified according to the standard 91/155 EEC

High-temp Deep Groove Ball Bearings for low speeds

High-temp Deep Groove Ball Bearings are especially coated bearings with an increased radial clearance. These products are usually used in applications with very high temperatures maximum to 400°C and slow speeds

High-temp Deep Groove Ball Bearings for fast speeds

GMW offers heat stabilized Deep Groove Ball Bearings, which are suitable for high temperatures to a maximum of 250°C and fast speeds.

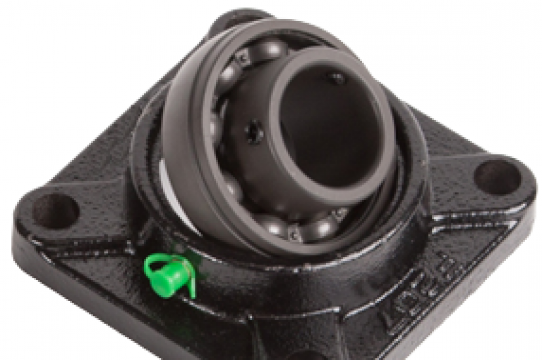

High-temp Radial Insert Ball Bearings for Low speeds

GMW offer High-temp Radial Insert Ball Bearings are especially coated bearings with an increased radial clearance. These products are usually used in applications with very high temperatures to a maximum of 350°C and slow speeds.

High-temp Radial Insert Ball Bearings for fast speeds

GMW offers heat stabilized and coated Radial Insert Ball Bearings, which are suitable for high temperatures to a maximum of 250°C and fast speeds.

High-temp spherical roller bearings

GMW offers open heat stabilized Spherical Roller Bearings, which are suitable for high temperatures to a maximum of 250°C and fast speeds.

Depending on the temperature inside the application, there are two versions: open and two Viton seals as standard (2RS1)

High-temp tapered roller bearings

GMW offers high-temp Tapered Roller Bearings . They are mounted in pairs in order to obtain a bearing unit sealed at both sides. The maximum operating temperature is 200°C

They are also coated with Manganese Phosphate on the roller, cage rings and possibly the entire product surface

High-temp Cam Followers for low speeds

High-temp Cam Followers with bushings outperform special grease or oil lubricated. GMW cam followers for high temperature up to 300°C. All High-temp Cam Followers come with the following benefits: Material AISI52100, Increased radial clearance (multiple of C5)

Manganese phosphate coating (according to EN ISO 9717).

Temperature conveyors, and steel mill equipment are typical applications.

High Temperature Grease

GMW uses only high-quality lubricants made by well-known manufacturers. Besides the temperature related standard lubricants, we also offer an extensive range of special grease options as well as individual lubrication as required by the customer on request.

Production

We specialise in rotational solutions for high temperature applications predominantly in the bearing. Our main product range includes High-Temp deep groove ball bearings, High-Temp taper roller bearings, High-Temp spherical roller bearings, High-Temp Radial Insert Ball Bearing, High-Temp Cam Followers. Which can handle temperatures from 150ºC to 400ºC

CASE STUDY

Multi-industry applications

GMW temperature bearings are specially designed for work applications in high temperature conditions.

All our GMW bearings are made of AISI 52100 steel and incorporate the most suitable greases for each thermal grade as a lubrication solution.

Our GMW temperature bearings are especially useful for applications in conditions subject to high temperatures such as trucks used in kilns for brick making, in furnaces for the ceramic industry, in rollers in working conditions at elevated temperatures in the steel manufacturing industry , aluminum manufacturing, glass manufacturing, Steel industry, Etc.

Iron and steel industry

Ordinary steel bearings don’t last long in high temperature environments like steel making. The casings expand, the polymers in the cage degrade and lubricants evaporate. Any one of these elements can cripple a bearing and halt production, never mind all three occurring at the same time. So GMW has developed a range of special bearings designed exclusively for use in ultra-high temperature applications such as steel making. With special materials, special cages, and special lubricants

Die-casting, Aluminium manufacturing

In the high pressure casting process, molten aluminum or aluminum alloy is scooped from the furnace and filled into the mold at fast speed and pressure.

Depending on the metal used, the part scoops the material into the mold continuously with the molten metal at a temperature range of 600° C – 700° C

The GMW suffix HT1 (350°C) is manufactured with a one-piece, high performance, low friction cage. The manganese phosphate coating of the GMW suffix HT1 helps the bearing ensure corrosion resistance and good adhesion of lubricants. will ensure equipment is operated safely and effectively in production

High temperature rollers

GMW high temperature bearings and bearing units are designed to deliver increased reliability, reduced complexity and decreased environmental impact in operating temperatures from 150°C (302°F) up to 400°C (752°F), making these products very suitable for applications in kiln trucks, roller hearth furnaces, and bakeries. Because GMW high temperature bearings correspond to the ISO dimensions of grease-lubricated bearings, production efficiencies and cost savings can be realized with a simple change to the GMW bearing solution.

Heating Pumps, Motor

There is always some fluctuation in the operating temperature of bearings within motors. Individual operating temperatures depend on elements such as the application of the motor and the ambient temperature. However, as a guide, 170°F or 80°C should be considered normal. As the temperature increases from this point, so does the risk of severe failure and motor damage.

At 190°F or 90°C, temperature alarms should engage. It is important not to ignore them and to take immediate action to find and treat the cause of the temperature rise

GMW bearing high-temp help

1) Prevents metal corrosion.

2) It can prevent the entry of foreign objects and seal the game.

3) Discharge friction heat, discharge slope temperature rising too high.

4) Reduce friction and wear, prolong bearing life.

Product News

We specialize in rotating solutions, combining our experience designing bearings for use high temperature. Therefore, we continuously invest in research and development (R&D) of new product lines or upgrading old products with the support of software experts.

GMW High-Temp Cam Followers suffix HT2/G (300°C) and low-temp L/2 (-73°C)

GMW High-Temp Cam Followers with bushings outperform ordinary grease or oil lubricated cam followers for high temperature 300°C (573°F), low temperature (-73°C and below) and submerged applications. The GMW cam[…]

Read moreHigh-temperature Deep Groove Ball Bearings 330°C – E330 (Enhanced+)

GMW deep groove ball bearings with the suffix E330°C (Enhanced+) are an enhanced temperature product of the HT3 series, it is designed to fill the upgrande of the temperature difference[…]

Read moreHigh-temp Radial Insert Ball Bearings T250X (250ºC)-Upgrande

GMW maker High-temp Radial Insert Ball Bearings for fast speeds with suffix T250X are a product upgrande of the T250 series are filled with a high-temp grease, which hardens after[…]

Read moreQuality and the enviroment

We are firmly convinced of the need to apply a very demanding quality policy in order to comply with the reliability, deadline and personalized service specifications demanded by our clients and suppliers.

The enviroment

We listen to our clients

Quality

Join us! It will only take a minute

Our workflow

GMW offers variouse products suitable for high temperature applications as well as normal applications. In to choose bearing high-temp, the temperature as well as the speeds and the load ratings have to be taken into account. Our employees will be glad to answer any question regarding our products

Requirement

Advice and quotation

Sign contract

Manufacturing processing

Product handover

Certification and warranty

Contact us

SHM TRADING AND PRODUCE CO., LTD

Address : 86 Le Trong Tan Street, Khuong Mai Ward, Thanh Xuan District, 100000 Ha Noi City, Vietnam

Hotline | WhatsApp : 0987 722 711

Tel : +84 24 6680 3301

Website : https://www.shm.net.vn

Email : bearings.shmhanoi@shm.net.vn

Email : marketing.shmhanoi@shm.net.vn